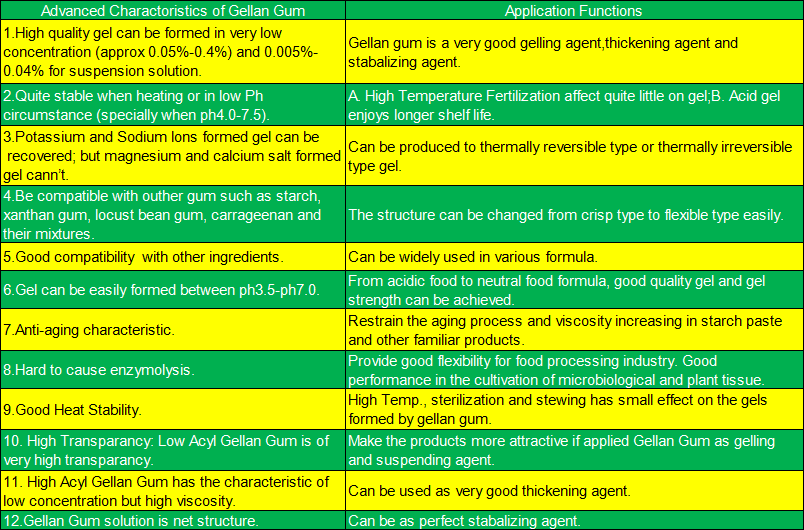

Compared with other hydrocolloids,Gellan Gum has many peculiar advantages:

1.Low dosage: The dosage of gellan gum is of 1/3-1/2 of K-Carrageenan or 1/5 of Agar Agar. For instance, for gels, dosage of gellan gum is 0.05%-0.4%. By controling the dosage of gellan gum in a lower lever, for example 0.01%-0.04%, it may help to form very weak gels, also called pre-gels. So the very low dosage gellan gum solution can be of good stabalizing and suspending agent. Especially for large grains in solution, the ONLY suspension agent is gellan gum.

2.Excellent acid stability:Gellan gum can help to form gels under pH from 3.5-7.5 and the gels are very stable.This is better than Carrageenan which can only be used in neutral solution, while pectins can only be used under acid solution.What's more, by controling the types of added ions, heat reversable and heat irreversable gels can be formed to meet different kinds of requirements.

3.Adjustable gel elasticity and rigidity:By using gellan gum only, various kinds of gels can be formed(for example, elastic gels and brittle gels) to meet the requirements of different products. This is different from carrageenan , agar or pectins who can form only one kind of gel.

4.High transparency:Low Acyl Gellan Gum can form high transparency gels;When dissolved in water, the solution made by low acyl gellan gum is also very clear and transparent.

5.Better taste-releasing ability;

6.Good compatibility with other ingredients and hydrocollids.